So, imagine this scenario: a patient in a remote area, far away from any medical facility, is in critical condition and desperately needs immediate medical attention. What can be done in these situations? Well, that’s where air ambulance services come into play. These specialized aircrafts are equipped with all the necessary medical supplies to provide critical care during transport. But have you ever wondered about the challenges that air ambulances face when it comes to having the right medical supplies? That’s where 3D printing comes in. In this article, we’ll explore how 3D printing technology is revolutionizing the way medical supplies are produced and used in air ambulance services. Hang on tight, because we’re about to take off into the fascinating world of 3D printing and its impact on air ambulance services.

3D Printing and Medical Supplies in Air Ambulance Services

Overview

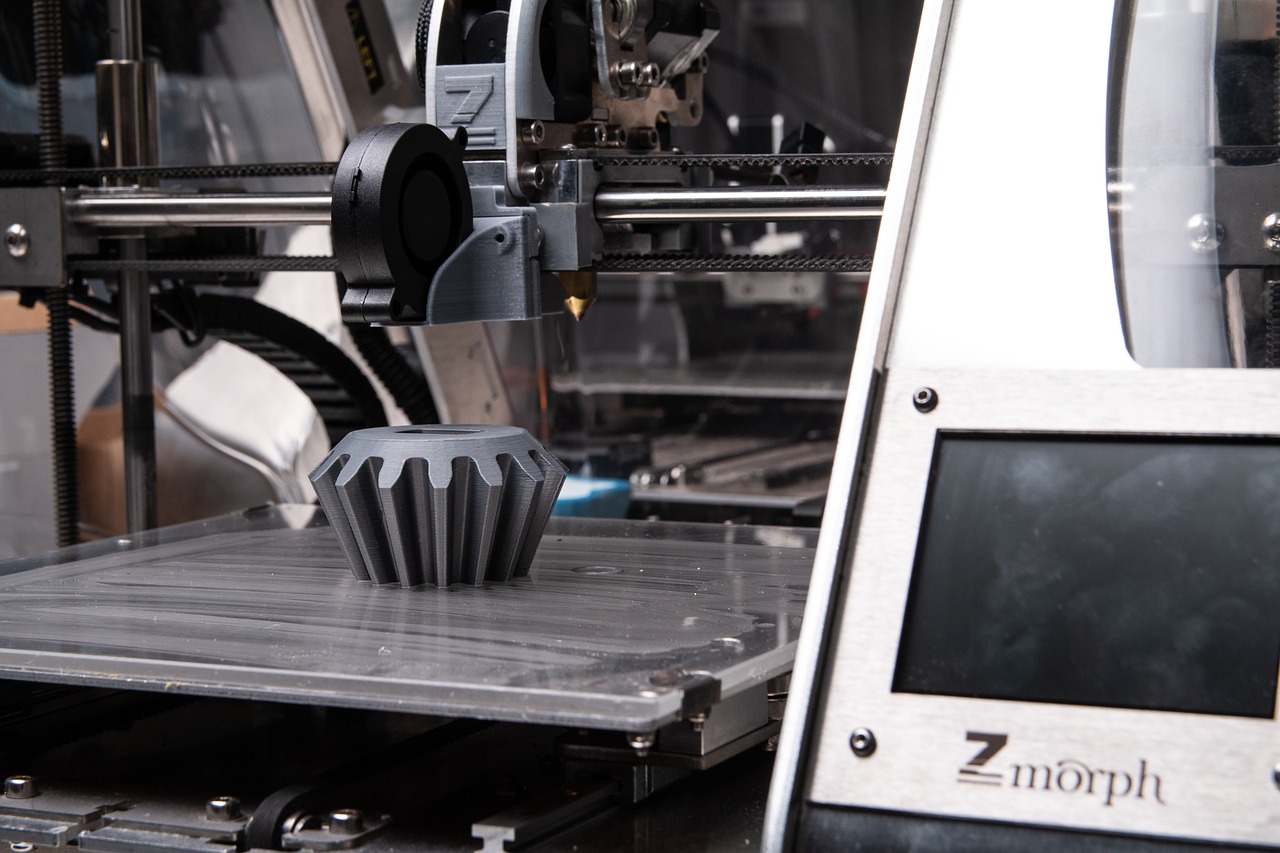

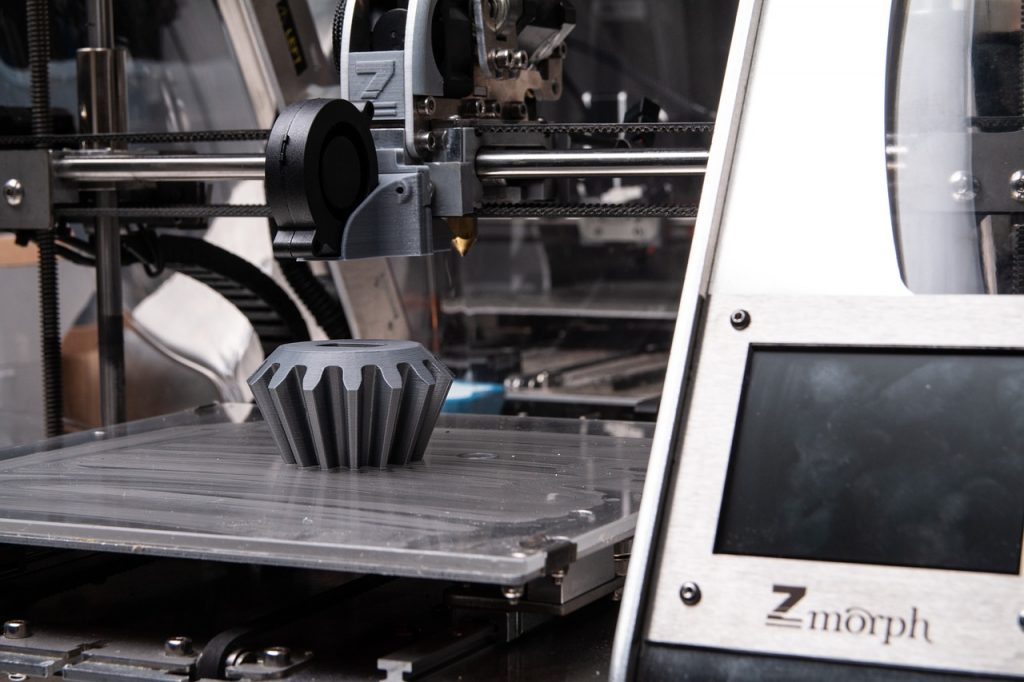

In recent years, advancements in technology have revolutionized the healthcare industry, and one innovation that has gained significant attention is 3D printing. This cutting-edge technology has the potential to transform various sectors, including air ambulance services. 3D printing involves the creation of three-dimensional objects through the layering of materials based on a computer-generated design. By harnessing the power of 3D printing, air ambulance services can enjoy a range of advantages and applications, ultimately improving patient care and outcomes.

Advantages of 3D Printing in Air Ambulance Services

The integration of 3D printing technology into air ambulance services offers numerous advantages. First and foremost, it allows for the production of customized medical devices. Each patient has unique requirements, and with 3D printing, air ambulance crews can rapidly manufacture personalized devices tailored to specific needs. This significantly reduces the waiting time and potential risks associated with acquiring pre-made devices, ultimately enhancing patient comfort and overall satisfaction.

Another notable advantage of 3D printing in air ambulance services relates to emergency prosthetics. In cases where patients require immediate prosthetic devices due to traumatic injuries, 3D printing provides a timely and cost-effective solution. With the ability to create prosthetics on-site, air ambulance crews can swiftly address a patient’s needs, reducing the pain and discomfort experienced while awaiting traditional prosthetics.

Furthermore, 3D printing allows air ambulance crews to produce surgical tools and implants. By creating these essential tools on-demand, medical professionals can ensure they have the necessary equipment readily available, regardless of the location or surrounding circumstances. This capability significantly enhances the efficiency of air ambulance services, enabling them to deliver prompt and effective care.

Additionally, 3D printing can be utilized in the production of pharmaceutical and biomedical supplies. From personalized medications to biocompatible implants, the versatility of 3D printing empowers air ambulance services to have access to a wide range of essential supplies. This reduces dependency on external sources and ensures that critical resources are readily available to meet the unique demands of each patient.

Applications of 3D Printing in Air Ambulance Services

- Customized Medical Devices

3D printing enables air ambulance crews to produce customized medical devices with precision and efficiency. Whether it’s orthopedic braces, splints, or supports, these devices can be swiftly manufactured to fit the specific needs of each patient. This level of customization not only improves patient comfort but also enhances treatment efficacy.

- Emergency Prosthetics

In cases where patients have suffered traumatic injuries requiring immediate prosthetics, 3D printing can be a lifesaver. With the ability to rapidly produce prosthetic limbs, air ambulance services can quickly alleviate discomfort and facilitate the patient’s journey towards rehabilitation and recovery.

- Surgical Tools and Implants

Having the ability to produce surgical tools on-site is a game-changer for air ambulance services. Whether it’s specialized instruments for specific procedures or patient-specific implants, 3D printing ensures that vital tools are always available at a moment’s notice, improving patient care and outcomes.

- Pharmaceutical and Biomedical Supplies

3D printing offers endless possibilities in the production of pharmaceutical and biomedical supplies. From personalized medications to biocompatible implants, this technology empowers air ambulance crews to meet the specific needs of each patient, regardless of their location or the availability of external resources.

Challenges and Limitations of 3D Printing in Air Ambulance Services

While 3D printing holds incredible potential for air ambulance services, it also presents certain challenges and limitations. One significant challenge is the need for highly skilled personnel to operate and maintain the 3D printers. Ensuring that air ambulance crews have the necessary training and expertise to effectively utilize this technology is crucial.

Another limitation of 3D printing in air ambulance services relates to the availability of resources and materials. While advancements in 3D printing technology have allowed for the use of a broader range of materials, there may still be limitations in terms of the types and quality of materials available for medical-grade applications.

Regulatory Considerations for 3D Printing in Air Ambulance Services

Given the critical nature of air ambulance services, regulatory considerations become paramount when integrating 3D printing technology. It is essential that medical devices and supplies manufactured through 3D printing adhere to strict quality control standards and comply with regulatory requirements. Authorities must develop comprehensive guidelines and regulations to ensure patient safety and promote the responsible use of 3D printing in air ambulance services.

Future Prospects of 3D Printing in Air Ambulance Services

As technology continues to advance, it is anticipated that the future of 3D printing in air ambulance services will be even more promising. The development of more advanced 3D printers capable of handling a broader range of materials and producing more intricate designs will expand the possibilities for medical applications. Additionally, advancements in artificial intelligence and computer-aided design (CAD) software will further enhance the accuracy and efficiency of 3D printing processes. These advancements will undoubtedly improve patient care and outcomes in air ambulance services.

Conclusion

In conclusion, the integration of 3D printing technology in air ambulance services offers numerous advantages and applications. From customized medical devices to emergency prosthetics and surgical tools, this cutting-edge technology has the potential to revolutionize patient care. However, it is crucial to address challenges such as skilled personnel and regulatory considerations to ensure the responsible and safe implementation of 3D printing in air ambulance services. With continued advancements, the future prospects for 3D printing in air ambulance services are exceptionally promising, paving the way for improved patient outcomes and the delivery of high-quality healthcare in the most challenging situations.